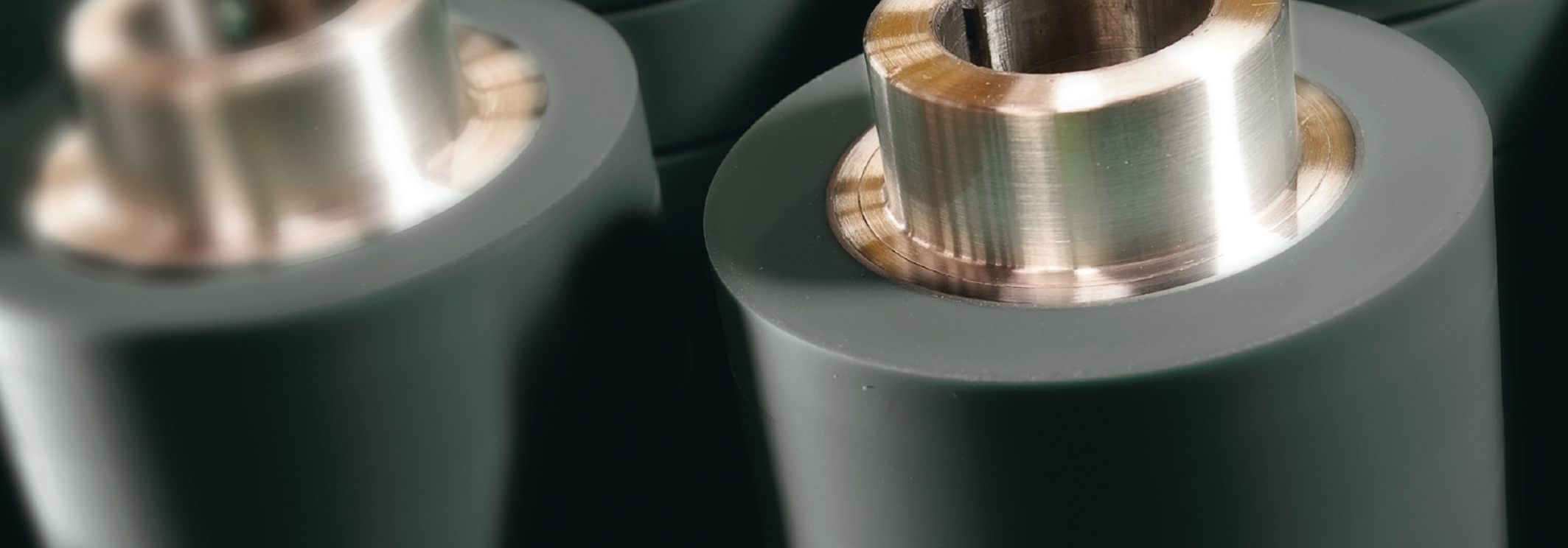

For the ultimate high release roller performance, X-tralease™ sleeves are the first choice of customers throughout the world.

Offering either FEP or PFA Teflon® coverings, X-tralease sleeves are intended for use in high temperature and / or adhesive applications where their outstanding performance means they do not suffer from surface build up and can be cleaned down in a fraction of the time of conventional rollers.

In addition to high release properties X-tralease sleeves have the following characteristics:

• Resistance to chemical attack

• Stable at high temperatures

• Consistent sleeve thickness

• Excellent dielectric properties

• Can be bonded to a wide range of hardnesses (60-93 Shore A)

X-tralease™ covers are ideal for use in the converting industry including cast film lamination, plastic film production and adhesive tape manufacture.

Technical Information

Key Features & Benefits

The ultimate in high release

• For adhesives & molten plastic

High bond strength to base rubber

• Sleeve will not detach in use

High resilience base rubbers

• Extended sleeve life

Typical applications

X-tralease™ products use an advanced range of FEP and PFA Teflon® sleeves of exceptionally uniform thickness, unique base rubbers, superior chemical etch and a new advance bonding system. X-tralease™ rollers provide a much longer life than conventionally sleeved rollers; they do not suffer from surface build up and can be cleaned in a fraction of the time of competitor’s rollers.

For the ultimate life and performance our Ultra Dynamic™ base rubber can be specified to help resist web edge marking. These rollers can be re-ground and re-sleeved several times to provide long term economies of use.

• Advanced aerospace bonding technology and production methods achieve lasting bond to base rubber

• 100% quality inspection of etched inner bonding surface for every sleeve during manufacture

• Tightly controlled manufacturing methods for sleeve fitting and bonding to the highest standards

• Roller free from surface defects ensured by 100% inspection of each finished sleeved roller

• Special cambers and surface profiles machined and measured to highest accuracy for special applications

Teflon® is a registered trademark of DuPont Dow Elastomers.

Delivering Dynamic Solutions

Specifications

Release properties: 5

Low friction properties: 5

Resistance to acid and wet chemicals: 5

Resistance to mineral oils: 5

Resistance to high temperature: 5

Resistance to flex fatigue: 4

Tear strength: 2

Abrasion resistance: 2

Resilience: 1

where 1= poor, 5= excellent

For further information on our services please call +44 (0)1633 869436 or fill out the form below.

Got a question about X-tralease™?

Please fill out this form and we’ll get back to you as soon as we possibly can.